What are the advantages of a jaw-type mobile crusher?

2025年5月12日

Working Principle of Cone Crusher

2025年5月12日

What are the advantages of a jaw-type mobile crusher?

2025年5月12日

Working Principle of Cone Crusher

2025年5月12日Blog

What processes are required to configure a sand and gravel aggregate production line?

With the arrival of 2023, the sand and gravel aggregate industry is about to usher in new development opportunities. The end of the pandemic and the booming infrastructure industry signal that the spring of the sand and gravel aggregate market is near. During this critical period, many professionals in the infrastructure industry are closely monitoring the dynamics of the sand and gravel aggregate sector. So, what processes need to be followed to design a sand and gravel aggregate production line, and what equipment needs to be configured?

Below is a process flow and equipment configuration plan for a typical manufactured sand and gravel aggregate production line:

Feeding Equipment

In the coarse crushing stage, feeding equipment mainly performs preliminary screening to remove impurities like soil, ensuring the efficiency of subsequent crushing.

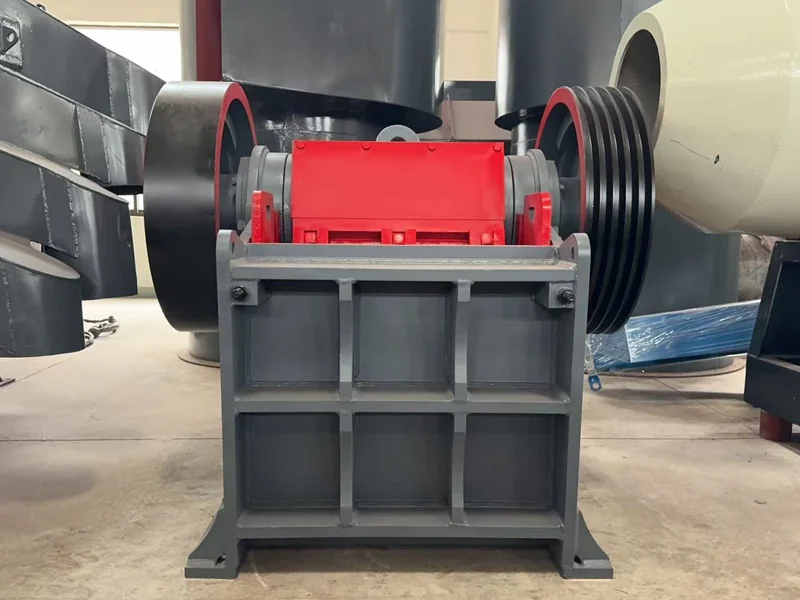

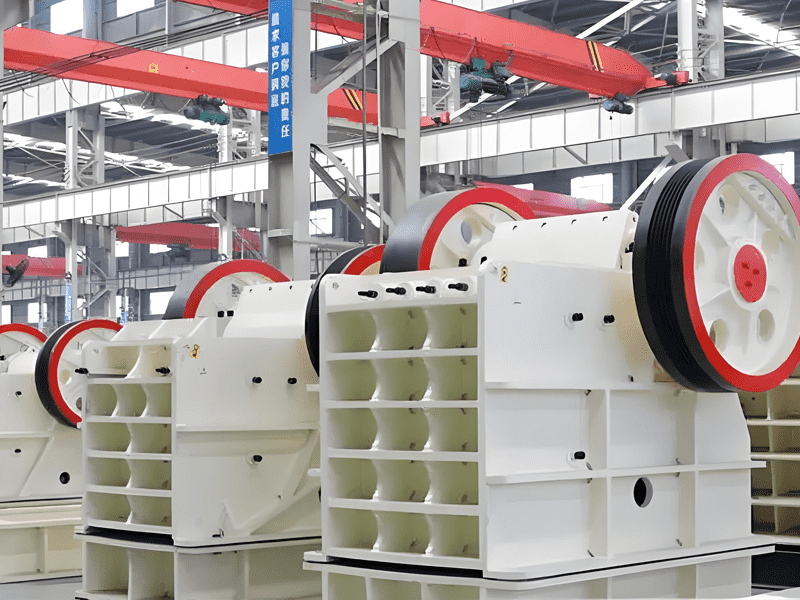

Coarse Crushing Equipment

In sand and gravel production, jaw crushers are commonly used as coarse crushing equipment to crush large materials into medium-sized pieces for further processing.

Intermediate Material Stockpile

After coarse crushing, the intermediate material stockpile is divided into two sections, running at different operation rates. If the equipment in the front section cannot operate due to feeding, transportation, or maintenance issues, the equipment in the back section can continue production using the stored intermediate material.

Pre-screening Before Medium Crushing

The purpose of pre-screening is to separate materials smaller than the medium crushing discharge size in advance to avoid unnecessary over-grinding. It also controls the amount of material and the maximum feeding size entering the medium and fine crushing or shaping equipment through the screen mesh size.

Medium Crushing Equipment

The medium cone crusher, along with pre-screening, forms a closed-circuit system. Pre-screening also serves as inspection screening. Materials smaller than 12mm can be directly used as raw materials for manufactured sand, preventing over-grinding and improving the crushing system's capacity.

Shaping and Sand Making Equipment

The third stage of crushing uses a vertical shaft impact crusher (VSI). This equipment has both crushing and shaping functions. After crushing and shaping, the material enters the finished product screen, forming a closed-circuit system.

Finished Product Screening Equipment

A flap valve is configured at the finished product screening discharge bin. Some finished aggregate can be returned to the vertical shaft impact crusher for re-crushing to adjust the final product ratio and enhance the flexibility of system control.

Whether crushing hard rock or soft rock, whether mobile or fixed crushing production, a production equipment configuration plan can be provided based on your needs.

Recommend Equipment

Solutions

Company Case

Request a Quote