What are the technical advantages of the impact crusher?

2025年5月8日

Material Requirements and Performance Analysis during Vibrating Screen Operation

2025年5月8日

What are the technical advantages of the impact crusher?

2025年5月8日

Material Requirements and Performance Analysis during Vibrating Screen Operation

2025年5月8日Blog

What are the types of crushers used in mining machinery?

Crushers are indispensable equipment in the mining and construction industries. There are many types of crushers, each with its unique working principle and application scenarios. Below is a brief introduction to several common types of crushers:

1. Jaw Crusher

The jaw crusher consists of a fixed jaw plate and a movable jaw plate. When the movable jaw plate periodically approaches the fixed one, the material is crushed by compression between the two plates. The liners on the jaw plates have teeth, which also contribute to splitting and breaking the material.

The PEX jaw crusher is a commonly used crushing device, mainly employed to break large ore or rock into smaller particles. It works through the squeezing and friction between the movable and fixed jaw plates. With a simple structure and easy operation, it is widely used in mining, building materials, and highway construction. Designed for efficiency and durability, it is suitable for processing various types and hardnesses of ore and rock, making it one of the essential crushing devices in modern engineering.

2. Cone Crusher

The cone crusher consists of a fixed outer cone and a movable inner cone. The inner cone performs eccentric motion around the centerline of the outer cone, crushing materials through compression and shearing between the two cones.

3. Hammer Crusher

The hammer crusher features hammers fixed on a rotating disc. Materials are crushed by the high-speed impact of the hammers and then carried to the screening bars below for discharge through the sieve holes.

4. Impact Crusher

The impact crusher uses rigid plate hammers fixed on a rotating disc. Materials are impacted and broken by the fast-rotating hammers, then thrown onto the impact plates for secondary crushing. Fragmented materials also collide with each other and are finally discharged from the bottom of the machine.

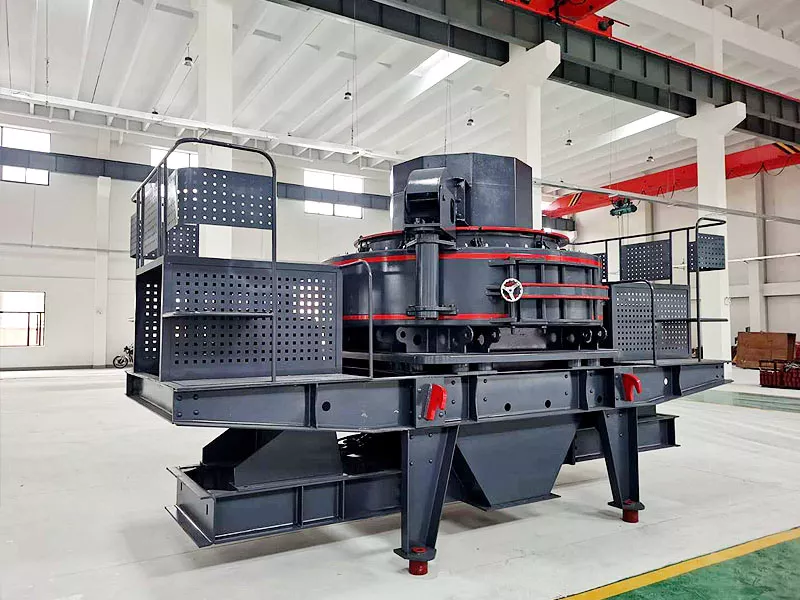

5. Vertical Shaft Impact Crusher (Sand Making Machine)

The main working part is a high-speed rotating impeller. Materials drop from the central feed pipe to the center of the impeller, then are thrown against the liners to be crushed. The crushed product is discharged freely along the circular space between the impeller and the liners.

The VSI sand making machine, also known as vertical shaft crusher, vertical shaft impact crusher, 5X sand maker, or the fifth-generation sand maker, is a new model developed by Dingbo. It transforms various rocks, sandstones, and river pebbles into construction-grade sand with uniform grain size and high compressive strength. Compared to natural sand and traditional hammer sand makers, it produces higher-quality sand that better meets construction requirements, thus improving building quality. The equipment is reliable, well-designed, easy to operate, and highly efficient.

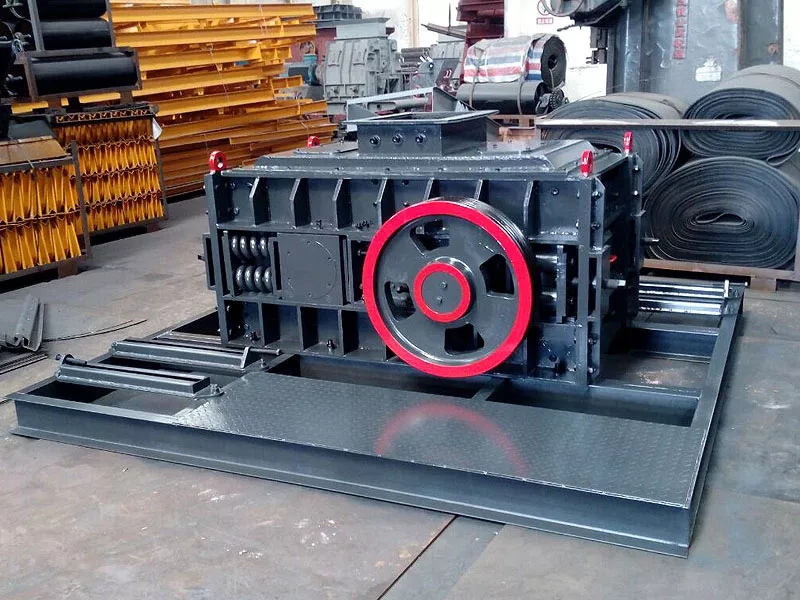

6. Roller Crusher

The roller crusher features two rollers rotating in opposite directions. Material is fed between the rollers, pulled in by their rotation, and crushed by compression. This type of crusher forces material discharge.

Recommend Equipment

Solutions

Company Case

Request a Quote