Jaw Crusher Maintenance Methods and Repairs

2025年5月7日

What are the types of crushers used in mining machinery?

2025年5月8日

Jaw Crusher Maintenance Methods and Repairs

2025年5月7日

What are the types of crushers used in mining machinery?

2025年5月8日Blog

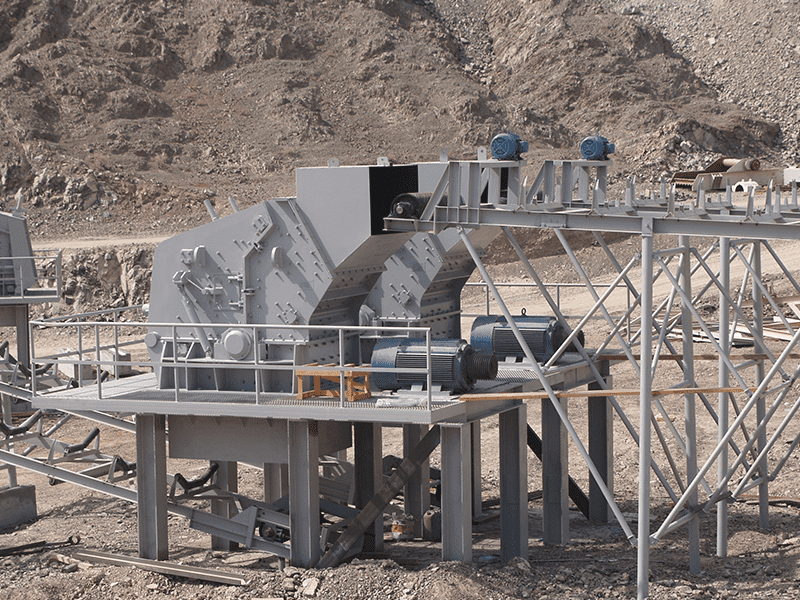

What are the technical advantages of the impact crusher?

The impact crusher is a widely used medium and fine crushing machine, highly favored in the mining industry. Its popularity stems from its wide application range, well-shaped discharged particles, and high cost-performance ratio. So, what advantages of the impact crusher attract users during operation?

- Effectively Processes Moist Materials and Prevents Blockages: The impact crusher can effectively handle materials with high moisture content without requiring a bottom screen plate, thus avoiding blockages. Additionally, the chute and impact plate are equipped with heating devices to further prevent material adhesion. In contrast, hammer crushers cannot be heated to prevent sticking and must be equipped with a bottom screen plate, which increases the likelihood of blockage.

- Suitable for Both Soft and Very Hard Materials: The impact crusher’s blow bar is firmly fixed to the rotor using a mechanical clamping structure, providing a large moment of inertia. This makes it suitable for crushing harder materials with lower energy consumption. Compared to hammer crushers (where the hammer is suspended), the rotor of the impact crusher has greater momentum.

- Flexible and Wide Range of Discharge Size Adjustments: The impact crusher allows multiple ways to adjust particle size, such as adjusting the rotor speed, the clearance plate, and the gap in the grinding chamber. These gaps can be adjusted mechanically or hydraulically, and the hydraulic system allows for easy adjustment via local control buttons or operating systems. Hammer crushers, on the other hand, can only adjust discharge size by replacing the bottom screen plate.

- Lower Wear on Wearing Parts and Higher Metal Utilization: The wear on the blow bar of the impact crusher only occurs on the side facing the material. When rotor speed is normal, the feed falls on the impact surface of the hammer, while the back and sides do not wear. Even the impact side experiences little wear. Moreover, the metal utilization rate of the blow bar can reach 45%-48%. For hammer crushers, which are suspended, wear occurs on the top, front, back, and sides of the hammer, resulting in more serious wear and a metal utilization rate of only about 25%. Additionally, the bottom screen plate of hammer crushers suffers significant wear and is complex to replace.

Recommend Equipment

Solutions

Company Case

Request a Quote