The Problem of Manufactured Sand Loss and Solutions

2025年5月13日

What equipment is needed to crush limestone, and what projects is limestone used for?

2025年5月13日

The Problem of Manufactured Sand Loss and Solutions

2025年5月13日

What equipment is needed to crush limestone, and what projects is limestone used for?

2025年5月13日Blog

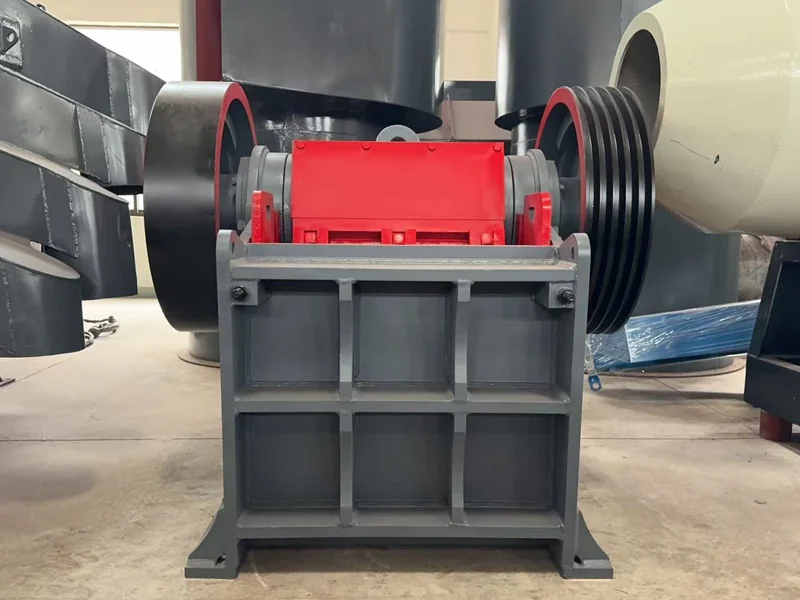

What are the measures to reduce the wear of the jaw crusher jaw plate?

In the mining production line, the jaw crusher, as a common crushing equipment, is mainly used at the front end of the production line to handle materials with high hardness. Due to the hardness of the materials, the requirements for the jaw crusher are relatively high, especially for the material of the jaw plates. Traditionally, jaw plates are mostly made of high manganese steel. Although high manganese steel has high hardness, it also leads to a large annual consumption of high manganese steel in China, thereby increasing crushing costs. At the same time, the wear of jaw crusher tooth plates is also a major issue.

To address these problems, in-depth research has been carried out, aiming to reduce the energy consumption of jaw crushers and extend the service life of the tooth plates.

By applying dissipative structure theory, damage mechanics theory, and the strain equivalence hypothesis, the relationship between the damage energy release rate and damage variables in the material crushing process was derived, thereby obtaining the critical threshold of the damage energy release rate during crushing.

During experiments, based on the structural parameters of the jaw crusher and the material distribution characteristics, Heavy Industry derived a mathematical model for the jaw crusher and motor power, and used this model to calculate the motor power of different types of jaw crushers. The validity of the mathematical model was verified through motor power tests conducted while crushing sandstone.

Through comparative analysis, fuzzy stochastic theory was used to perform stress analysis on the movable jaw plate of the PE series jaw crusher. Ansys software was used to carry out stress calculations on the tooth plate, and the structural parameters of the tooth plate were optimized. The improved tooth plate reduced stress concentration, extended its service life, saved manufacturing materials, and lowered the energy consumption during material crushing.

These studies have achieved significant results, providing effective solutions to the problems of energy consumption and tooth plate lifespan in jaw crushers. Heavy Industry will continue to focus on research in these areas, taking the reduction of jaw crusher energy consumption and the extension of tooth plate life as key future research topics, and will invest in developing more energy-efficient and environmentally friendly jaw crusher equipment.

Recommend Equipment

Solutions

Company Case

Request a Quote