What is the difference between a sand making machine and a crusher?

2025年5月12日

What is the ideal particle size of the discharged material from a ball mill?

2025年5月13日

What is the difference between a sand making machine and a crusher?

2025年5月12日

What is the ideal particle size of the discharged material from a ball mill?

2025年5月13日Blog

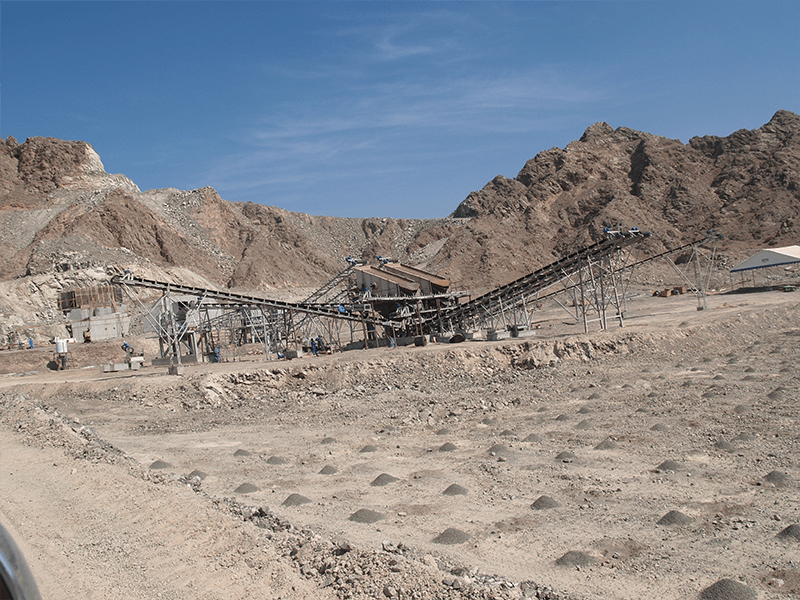

What are the components of a sand and gravel production line?

A sand and gravel production line requires a variety of equipment to ensure a complete process from raw material extraction to finished aggregates. A standard production line typically includes the following stages and equipment combinations:

Feeding Stage:

Large rocks extracted from the mountains are transported to the feed hopper by loaders and then continuously and evenly fed into the primary crushing equipment, such as a jaw crusher, via a feeder. Commonly used equipment at this stage is the vibrating feeder, which has a simple structure and occupies little space.

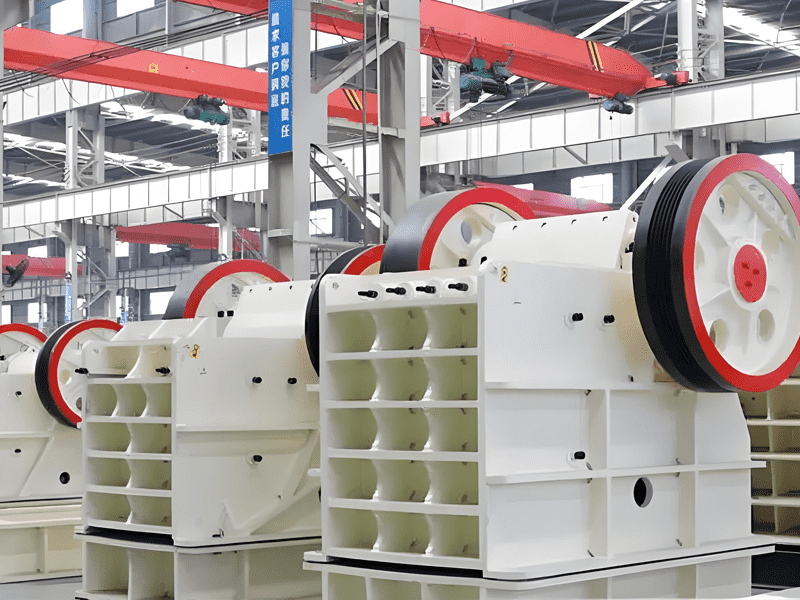

Crushing Stage:

The crushing process involves multiple stages, primarily including coarse and medium-fine crushing equipment. Crushing machines can be categorized based on their working principles into compression-type and impact-type crushers. Compression-type crushers, such as jaw crushers and cone crushers, are suitable for hard materials. Impact-type crushers, such as hammer crushers and impact crushers, are better suited for medium-hard materials.

Sand Making Stage:

This stage usually follows the crushing phase and aims to produce manufactured sand based on market demands. Sand making machines can further crush the processed stone into artificial sand with a particle size of less than 5 mm.

Screening Stage:

Screening serves as an auxiliary process, using vibrating screens to separate crushed or sanded materials into various product sizes and gradations to meet different specification requirements.

Conveying Stage:

Conveying, like screening, is also an auxiliary process. Belt conveyors are used to transport materials between each stage and the final storage. The number of conveyors required depends on the specific process layout.

Recommend Equipment

Solutions

Company Case

Request a Quote