Jaw crushers are particularly effective when crushing pebbles

2025年5月7日

Jaw Crusher Maintenance Methods and Repairs

2025年5月7日

Jaw crushers are particularly effective when crushing pebbles

2025年5月7日

Jaw Crusher Maintenance Methods and Repairs

2025年5月7日Blog

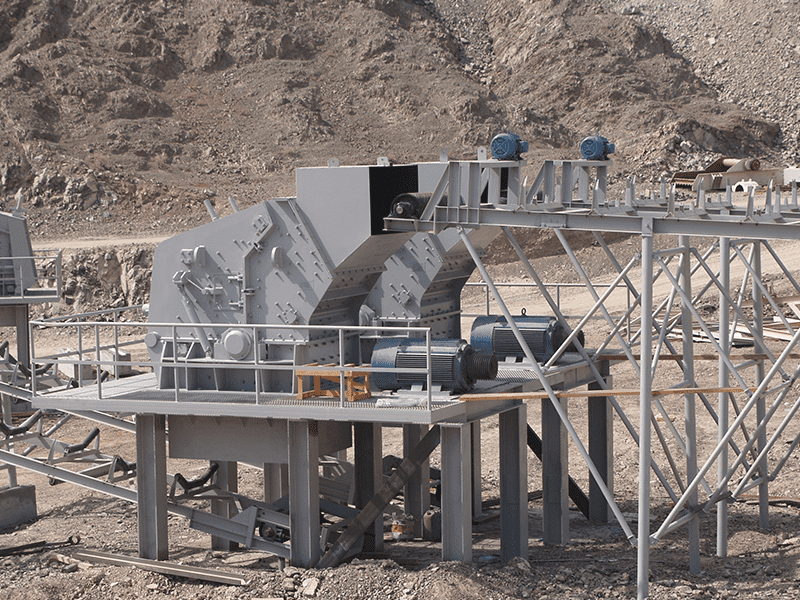

What are the characteristics of an impact crusher?

The impact crusher, also known as the impact breaker, has been in the market for many years and has played a key role in the development of society. It has been widely used in the construction of railways, highways, hydropower projects, and other infrastructure, making significant contributions to the aggregate crushing process. The introduction of the impact crusher has been greatly appreciated by customers. Over the past 60 years, the impact crusher has been used both nationally and globally, with tens of thousands of units applied in various industries. So, what are the main characteristics of the impact crusher?

1. Applicable Material Range

The impact crusher can crush hard materials with a compressive strength not exceeding 350 MPa. When the machine is operating, the rotor rotates at high speed under the drive of the motor. When the material enters the area of the plate hammer, it is impacted and crushed by the plate hammer on the rotor, then thrown onto the impact device for further crushing. The material is then bounced back from the impact liner to the plate hammer area for re-crushing. This process repeats, with the material entering the first, second, and third impact chambers for further crushing, until the material is crushed to the required particle size and discharged from the outlet. In recent years, the processing and crushing of recycled aggregates from construction waste has seen significant contributions from impact crushers. The impact crusher is mainly used for medium and fine crushing and can work alongside jaw crushers and sand making machines.

2. Diverse Discharge Adjustment Methods of Impact Crushers

The impact crusher has a significant advantage in adjusting discharge particle sizes. Compared to other crushers that adjust the discharge opening size, the impact crusher can adjust the product size in three ways. First, by adjusting the speed or diameter of the rotor. Increasing the rotor speed or diameter can extend the crushing time, thereby adjusting the product's particle size, increasing output, and improving material crushing efficiency. Second, by adjusting the distributor to change the product's particle size. Adjusting the distributor and reducing its opening can increase the overflow supply flow of material, limit the collision movement of the material in the crushing chamber, shorten the residence time of the particles in the crushing chamber, and improve the crusher's throughput. Third, by adjusting the gap in the grinding chamber to change the final product's particle size. The gap adjustment of the grinding chamber can be done either mechanically or hydraulically, with the hydraulic method allowing fast and convenient gap adjustments via buttons or control systems.

3. Less Wear on Easy-to-Wear Parts of the Impact Crusher

The wear on the plate hammer of the impact crusher only occurs on the side facing the material. When the rotor speed is normal, the material falls on the surface of the plate hammer, and the back and sides of the plate hammer do not experience wear. Even the side facing the material does not wear much. Additionally, the bottom grinding rods are easily replaceable. The metal utilization rate of the impact crusher's plate hammer can reach 45-80%.

4. Convenient Part Replacement and Easy Maintenance of the Impact Crusher

Replacing parts in the impact crusher does not require much labor or material resources. When replacing the rotor plate hammer, the hydraulic lift can be used to raise the rear cover of the impact crusher for easy replacement, which is quick, convenient, and saves time and effort.

5. Full Range of Specifications and Diverse Configurations of Impact Crushers

The impact crusher has three main series with a variety of models, suitable for handling materials from tens of tons to hundreds or even thousands of tons. This wide range of specifications can meet customer needs to a large extent.

Recommend Equipment

Solutions

Company Case

Request a Quote