What are the types of crushers used in mining machinery?

2025年5月8日

Why Can’t the Motor of a Raymond Mill Start?

2025年5月9日

What are the types of crushers used in mining machinery?

2025年5月8日

Why Can’t the Motor of a Raymond Mill Start?

2025年5月9日Blog

Material Requirements and Performance Analysis during Vibrating Screen Operation

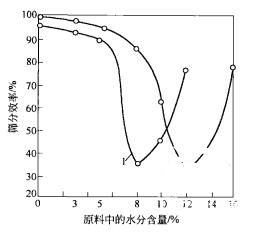

1. Moisture Content

The moisture content of the material, also referred to as humidity or water content, has a significant impact on the material screening process. The moisture attached to the surface of the material is called external moisture, and it affects the material’s flowability on the screen mesh. For example, when screening certain types of anthracite coal, if the moisture content reaches 6%, the screening process becomes difficult because the moisture basically covers the surface of the coal. In contrast, lignite with a higher porosity can still be screened effectively even if the moisture content reaches 45%. The effect of moisture is especially significant when screening on fine-pore screens. Fine particles have a larger specific surface area, and their external moisture content is also high, which can cause the fine particles to stick together and attach to larger pieces, blocking the screen holes.

2. Clay Content

If the material contains a mixture that tends to agglomerate, such as clay, screening can be challenging even if the moisture content is very low. Clay materials tend to clump together during screening, causing fine clay particles to mix with the screened product and easily clog the screen holes. Clay-rich and viscous materials are usually only screened with larger mesh screens in special cases. In wet screening, the productivity of the screen is higher compared to dry screening, depending on the screen hole size. The amount of water consumed in wet screening depends on the nature and quantity of the clay mixture, fine clay, and dust particles.

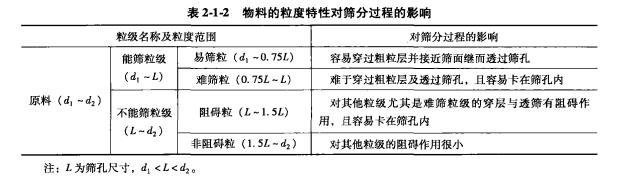

3. Particle Size Characteristics

The particle size characteristics that affect the screening process mainly refer to the content of various particle grades in the raw material that are significant to the screening process. When there is a low content of fine particles in the raw material, and the material on the screen is too coarse, a pre-screening method can be applied. By using a larger mesh auxiliary screen, the over-coarse particles can be pre-screened, and then finer materials containing a large number of fine particles can be screened to improve efficiency and extend the life of the screen mesh.

4. Density Characteristics

When all the particles in the material have the same density, it does not affect the screening. However, when there is a density difference between coarse and fine particles, the situation changes. For example, if the coarse particles have a lower density and the fine particles have a higher density, the screening is relatively easy. Conversely, if the coarse particles have a higher density and the fine particles have a lower density, the screening process becomes relatively difficult.

Recommend Equipment

Solutions

Company Case

Request a Quote