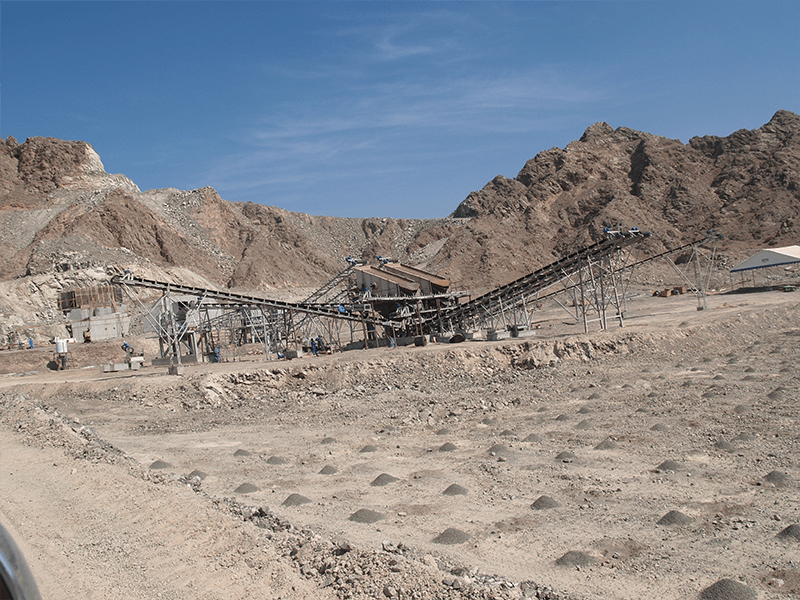

Introduction to Crushing Equipment for Granite

2025年5月14日

Introduction to Crushing Equipment for Granite

2025年5月14日Blog

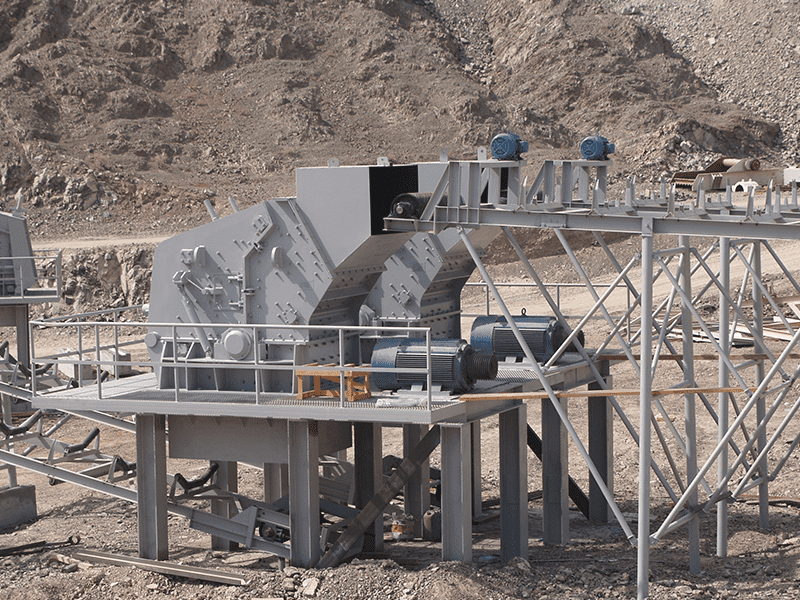

Impact Crusher’s Crushing Principle, Structural Features, and Applications

The impact crusher is a type of mechanical equipment that uses a high-speed rotating rotor and impact plates to crush materials through impact. During the operation, the electric motor drives the rotor to rotate at high speed. When materials enter the hammer action area, they are struck and crushed by the hammers on the rotor. Then, they are thrown towards the impact device for further crushing, after which they bounce back from the impact liner to the hammer action area for re-crushing. This process repeats continuously until the material is crushed to the desired particle size, after which it is discharged through the outlet.

The structural features of the impact crusher include:

- Multi-stage impact chamber: The impact crusher has sufficient crushing space, making it suitable for crushing large materials.

- Adjustable impact plate angle: By adjusting the angle of the impact plate, it ensures that materials are at an appropriate angle during repeated impacts between the impact plate and rotor, improving crushing efficiency.

- Energy consumption reduction: The work process of the impact crusher can effectively reduce energy consumption during the crushing process.

- Overload protection: The impact plate adjustment system can also serve as an overload protection device for the entire machine, preventing damage to the equipment caused by foreign objects or uncrushable materials.

- Easy maintenance: The frame of the impact crusher is made up of three parts, making it easy to replace hammers, impact plates, liners, and other components during maintenance operations.

- Monitoring system: The impact crusher's monitoring system can constantly monitor the operating status of the crusher, ensuring safe and reliable operation.

- Drive system: The crusher uses an electric motor + mechanical coupling + V-belt + crusher setup to enhance the motor's starting performance and reduce operating costs.

The technical advantages of the impact crusher include:

- Uniform discharge granularity: The discharge material is cubic, with fine powder and low dust content, making it suitable for indoor industrial plant work.

- Low operating cost: The crusher is lightweight, with small size, low dynamic and static load values, reducing construction costs. It also requires lower motor power, reducing equipment power consumption.

- Long service life of wear parts: The long-term operating cost is low.

Recommend Equipment

Solutions

Company Case

Request a Quote