Blog

Introduction to Raymond Mill

This comprehensive article provides an in-depth look at the Raymond mill, a versatile and widely used grinding machine. It covers the applications of Raymond mill in various industries, including mineral processing, chemicals, and construction, highlighting its ability to grind over 300 different materials with Mohs hardness ≤7 and humidity ≤6% to a fineness between 80 and 800 mesh. The article then delves into the structural features of the Raymond mill, emphasizing its compact design, reliable operation, and low failure rate. It explains the working principle of the mill, detailing the grinding process and the role of various components. The article also highlights the reliable quality of the Raymond mill, comparing it favorably to ball mills in terms of efficiency, power consumption, and initial investment. Finally, it provides essential maintenance guidelines to ensure optimal performance and longevity of the equipment. This article serves as a valuable resource for understanding the capabilities and operational aspects of the Raymond mill.

Why Can’t the Motor of a Raymond Mill Start?

This article addresses the critical issue of a Raymond mill’s motor failing to start, which halts production. It outlines the primary causes for this problem, including power issues, low overcurrent relay settings, excessive motor load, and incorrect wiring. The article then provides practical solutions for each cause, such as checking and repairing electrical components, adjusting relay settings, reducing the motor load, and correcting wiring errors. Understanding and addressing these issues is crucial for maintaining uninterrupted operation and optimal performance of the Raymond mill.

Material Requirements and Performance Analysis during Vibrating Screen Operation

This article explores the crucial material requirements and their impact on vibrating screen performance. Key factors include moisture content, where external moisture affects flowability and can lead to clogging, especially in fine-pore screens. Clay content is another critical aspect, as materials prone to agglomeration, like clay, can cause screen clogging even with low moisture levels. Particle size characteristics, particularly the distribution of particle grades, influence screening efficiency, with pre-screening methods improving performance when fine particle content is low. Finally, density characteristics of the material, where differences in density between coarse and fine particles affect screening ease, are discussed. Understanding these material properties is essential for optimizing vibrating screen operation and achieving efficient separation results.

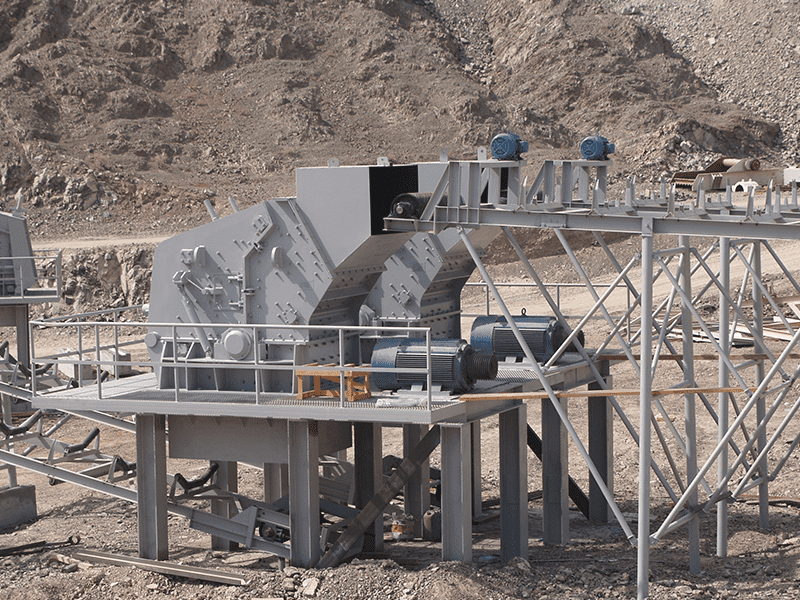

What are the types of crushers used in mining machinery?

This article discusses various types of crushers used in mining machinery, each with unique working principles and applications. The jaw crusher, with its fixed and movable jaw plates, is suitable for breaking large ore or rock into smaller particles and is widely used in mining and construction. The cone crusher uses an eccentric motion to crush materials between two cones. The hammer crusher employs high-speed hammers for impact crushing, while the impact crusher uses rigid plate hammers for breaking materials. The vertical shaft impact crusher, also known as a sand making machine, features a high-speed rotating impeller for producing construction-grade sand. Lastly, the roller crusher uses two rotating rollers to compress and crush materials. These crushers are essential for processing various types and hardnesses of ore and rock in the mining and construction industries.

What are the technical advantages of the impact crusher?

The impact crusher is favored in the mining industry for its efficiency and versatility. It excels in handling moist materials without clogging, a common issue with hammer crushers that require a bottom screen. The impact crusher's design, featuring a heating device on the impact plate, prevents material adhesion. It also offers a wider range of discharge adjustment. Furthermore, the impact crusher experiences less wear and has a higher metal utilization rate compared to hammer crushers, which wear on multiple sides and have a lower utilization rate. These factors contribute to the impact crusher's popularity and cost-effectiveness.