In which fields can a jaw crusher be used? What are its features?

2025年5月14日

Introduction to Crushing Equipment for Granite

2025年5月14日

In which fields can a jaw crusher be used? What are its features?

2025年5月14日

Introduction to Crushing Equipment for Granite

2025年5月14日Blog

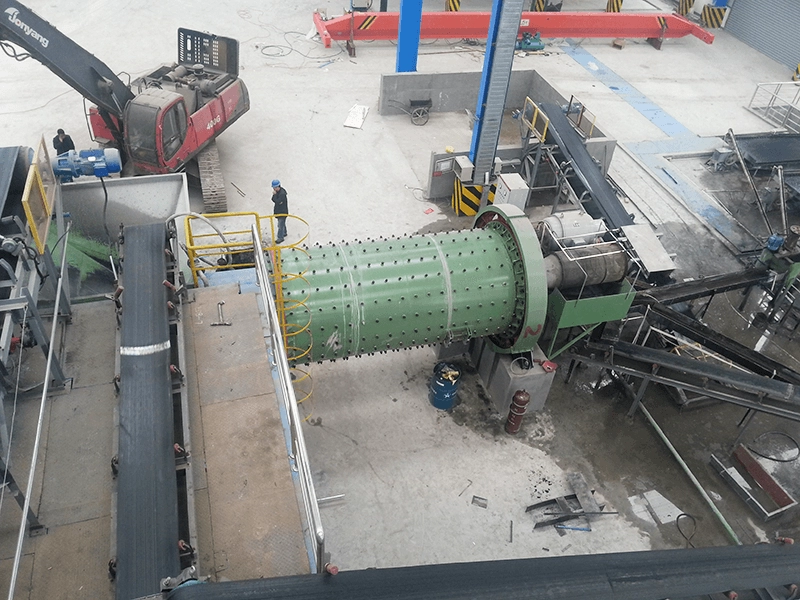

Definition and Maintenance of Ore Crusher

Ore crushers play an important role in fields such as mining, smelting, building materials, highways, railways, water conservancy, and the chemical industry. According to the physical and chemical properties of the material to be crushed and the environmental conditions of the production site, different types of ore crushers can be selected to achieve the final crushing process. Common ore crushers include jaw crushers, impact crushers, cone crushers, and sand making machines. Crushing equipment, screening equipment, and other auxiliary equipment together constitute a complete product production line.

In the construction of a sand and gravel aggregate production line, crushing equipment is the core component. Selecting appropriate crushing equipment directly affects the economic benefits and profit recovery of the entire production line.

When selecting an ore crusher, the following issues need to be considered:

- Understand the material to be crushed: Different materials require different types of crushers. For example, high-hardness rocks such as quartzite, basalt, granite, etc., require jaw crushers with strong crushing capacity. For ores with low compressive strength, such as gypsum and anthracite, hammer crushers can be selected. For soft and medium-hard materials such as limestone and sandstone, impact crushers can be used.

- Ore crusher output: Select the appropriate model of crusher according to the required output of the production line. A crusher with excessive processing capacity will lead to resource waste, while insufficient capacity cannot meet market demand.

- Ore crusher quality: The quality of the crusher directly affects the price and production efficiency. Selecting high-performance, reliable, and technologically advanced crushing equipment can produce high-quality and high-output finished sand and gravel to meet the high demand and strict requirements of the construction market.

- Dingbo Heavy Industry after-sales service: Good after-sales service is an important factor when purchasing equipment. Crushing equipment often endures high-intensity work and requires regular maintenance. Choosing a mining equipment manufacturer with standardized and scalable after-sales service ensures the normal operation of the equipment and prolongs its service life.

Daily Maintenance of Ore Crushers Includes:

- Routine maintenance: To ensure that the mining crusher is in good technical condition, reduce downtime due to failures, improve the equipment's integrity rate and utilization rate, reduce wear, extend service life, lower operating and maintenance costs, and ensure safe production, daily maintenance of the crusher must be strengthened.

- Lubrication maintenance: Paying attention to and promptly performing lubrication of friction surfaces can ensure the normal operation of the crusher and extend its service life. Lubricating grease must be replaced every three months, and the bearing raceways should be thoroughly cleaned with clean gasoline or kerosene when changing the oil.

- Bearing maintenance: The bearing part is the most easily damaged component and must be regularly maintained and lubricated to extend its service life.

Recommend Equipment

Solutions

Company Case

Request a Quote