What are the measures to reduce the wear of the jaw crusher jaw plate?

2025年5月13日

How to prevent rust on crushing equipment during the rainy season.

2025年5月14日

What are the measures to reduce the wear of the jaw crusher jaw plate?

2025年5月13日

How to prevent rust on crushing equipment during the rainy season.

2025年5月14日Blog

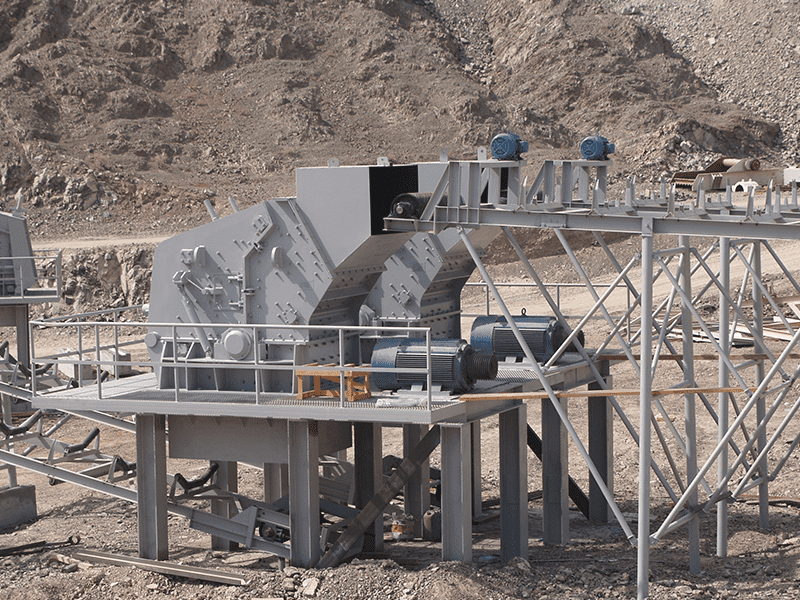

What equipment is needed to crush limestone, and what projects is limestone used for?

Choosing a high-quality dolomite crusher is essential to ensure product quality and production efficiency. A dolomite crusher can process dolomite into various products to meet the needs of multiple industries, including construction materials, ceramics, glass, refractory materials, chemicals, agriculture, environmental protection, and energy saving. The following are several key factors to consider when selecting a dolomite crusher:

1. High Output of the Dolomite Crusher

Due to the strong market demand for dolomite products, manufacturers should choose a dolomite crusher with high output. If the budget allows, priority should be given to purchasing large-scale equipment to ensure production efficiency. Even with a limited budget, high-performance equipment should be chosen, as high-output machines are typically produced by technically advanced manufacturers and can deliver high performance and productivity even in compact models.

2. Strong Compression Resistance of the Dolomite Crusher

Since mined dolomite varies in size and may contain other substances, choosing a crusher with strong compression resistance can improve production efficiency and eliminate the need for manually breaking large pieces or processing through other equipment. The machine should have sufficient compressive strength to handle mixed hard materials. Pre-screening dolomite before crushing can also help prolong the equipment's lifespan.

3. Durable Wear-Resistant Parts

When selecting a dolomite crusher, it is important to ensure that its wear-resistant parts are made of high-quality materials. This helps extend the equipment’s service life and reduces downtime caused by maintenance and part replacement. The durability of wear-resistant parts directly impacts the overall performance and operating cost of the crusher.

Recommend Equipment

Solutions

Company Case

Request a Quote